Products

1.Photoluminescent Pigment

The photoluminescent pigment is made from rare earth elements

through a hi-tech process. It absorbs light(natural day light or

electrical lamp light) for about 10~15minutes and then emits a

visible light for more than 12 hours in the dark. It is free of

radioactive and toxic materials and it is chemically stable. It

can be added into paints, inks, plastics and makes them

luminescent.

Technical data:

| Type |

Color |

Initial mcd/m2 |

Decay Time |

Life Time |

| BT201 |

yellow-green |

>15000 |

>12h |

>15y |

| BT401 |

yellow-green |

>7000 |

>6h |

>15y |

| BT501 |

yellow-green |

>4800 |

>3h |

>15y |

| BL201 |

blue |

>6000 |

>12h |

>15y |

Particle size:100 mesh~400 mesh

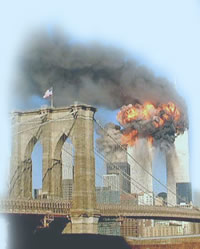

2.Photoluminescent Safety Signs

The photo luminescent safety signs are printed with the

photoluminescent pigment, which absorbs light (natural day light

or electrical lamp light)for about 10~15 minutes and then emits a

visible light for more than 12 hours in the dark. It is free of

radioactive and toxic materials. The photoluminescent safety signs

do not need electricity. They are energy saving, easy to fix and

have no failure in its function. The photoluminescent safety signs

are widely used in modern public buildings, hotels, subways,

stadiums and military bases.

COMPARISON

BETWEEN THE TRODITIONAL AND THE PHOTOLUMINESCENT SAFETY SIGNS

|

|

Item |

Photoluminescent Safety Signs |

Troditional electric signs |

|

1

|

powr line |

not needed |

needed |

|

2

|

energy source |

light(electrical or natural) |

electricity |

|

3

|

function stability |

no failure in function |

not stable |

|

4

|

energy saving |

no energy consumption |

consume electricity |

|

5

|

life time |

> 10 years |

2~3 years, |

|

6

|

cost |

low |

high |

|

7

|

maintenance cost |

0 |

high |

|

8

|

type of installation |

hanging / adhesive |

pre-built |

|

9

|

decay time in case of powr-cut |

>12 hours |

1.5~2 hours in normal case |

|

10

|

location of installing |

as needed |

where power is available |

|

11

|

thickness of the signs |

0.2cm~1cm |

3cm~5cm |

|

12

|

base material of the signs |

aluminum or other materials |

glass or acrylic |

|

13

|

appearance |

good, not easy to be broken |

easy to be broken and easy to get dust |

3.BL

(UVL)Pigment

The BL pigment emits a colored light when exposed to the ultraviolet

light (2537nm~3650nm). The pictures and letters coated with the

BL pigment give out a fascinating effect. Therefore it is widely

used in the interior design of bars, kara OK rooms and performing

stages. It is also used in making invisible inks and the anti-forgery

industry.

Looking for

Worldwide

Distributors and

Agents |